Inkjet markers are necessary accessories for all cable manufacturers to meet the constant demand of customers to print a marking on the outer sheath.

Over time, this marking has become more personalized and longer (it may be necessary to provide markings with 200 characters and even more) to be able to insert more and more information and aesthetic characteristics:

The time required to enter the complete legend requested by the customer in the inkjet marker certainly represents a cost. Although in theory the markings can be stored in the printer memory and then recalled, they must in any case be searched in the archive and then customized / updated. This setting is always performed with the production line stopped, by personnel who are not always used to working with keyboards and special symbols, often even in non-optimal lay-out conditions.

The set-up time for the change of marking on an ink-jet marker can be estimated on average in 10/15 minutes. The realities in special cable production companies are very different from each other and while in the past the production / marking changes were 1 or 2 per shift, today it is easy to achieve even 5 or 6 changes per shift. Shifts can also vary from 1, 2 and even 3 per day. Therefore it is easy to achieve 1500 - 2000 production / marking changes per year and per line. This means that for each line, 250 - 350 hours / year are committed to the setting of the marker alone, with a company cost that can be estimated between 10,000 and 15,000 Euro / year.

The great variability, the length and the ad hoc prescriptions, the situation and the working layout create the conditions for making mistakes in the marking of the sheath, errors that the customer is almost never willing to accept. For this it is necessary to delete / re-mark the cable and in extreme cases remove and redo the sheath with the correct marking. In both cases, these are very expensive operations especially in terms of time, because they must be carried out with handcrafted equipment that requires a lot of manpower.

The KAIZEN system, developed by TOYOTA to improve efficiency and effectiveness in production, has taught that:

Each step that does not produce added value for my customer and therefore for me, produces what the Japanese call MUDA (waste)

This means that reducing or eliminating MUDA is equivalent to optimizing processes, improving the efficiency and effectiveness of activities. Through these operations and therefore the reduction of downtime, great results and savings can be achieved, creating the culture of LEAN THINKING.

SIF, which has always paid attention to these increasingly important aspects for companies, has already designed and developed a High Technology system in 2014, which allows you to prepare and load into the inkjet printer in LEAN mode everything you need to print without mistakes.

The iLP system, in whose name i means innovative, intelligent, intuitive, illustrated, interactive and LP means Lean Printing, is made of two parts:

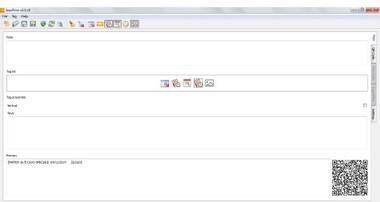

- iLP_QRge PC software

- iLP_QRtc transcoding device

It is a software that is installed on a standard PC, which allows you to compose the complete marking of all information, through icons in the DRAG & DROP system.

The icons represent the different types of choices needed to compose the marking "string", such as:

- font height

- indication of metric marking

- space between indication of meters and marking

- legend to be marked on the cable

- logos and special characters

… and much more.

This string can be freely composed, thus alternating logos and marking without constraints. While composing the marking string, the software creates a QR CODE (a code that allows you to contain a very large number of characters). The composed QR CODE is universal or neutral so that it can be recognized and printed by any type of printer. It can be printed on an adhesive label, on a white sheet, directly on the production order or even on the cable project sheet (to import the QR CODE image in the company's internal management program or in the project sheet, the type of standard shall be requested to SIF). Some utilities allow you to view the QR CODE in large, to view the different logos and create new ones, to show the different heights of the characters, to define some most used selections as default ones.

It is a QR CODE transcoding device, consisting of a gun to read the QR CODE and a high-tech smart system with a 7 "graphic touch screen, connected to the inkjet printer via the RS232 interface.

The smart system is programmed to recognize the QR CODE, generated by the iLP_QRge software, and to communicate with the related connected inkjet printer.

With the iLP system it is possible to eliminate the operator time required for loading and preparing the printer: just a simple click, about 2 seconds. A study and an analysis within different companies has allowed us to calculate that an average of 10/15 minutes can be saved, but in some particular situations they can reach up to 30 minutes, for each legend to be marked on the sheath of the cable in production. Furthermore, the costs due to remaking / re-marking of the cables due to errors in inserting the legend can be eliminated.

The composed QR CODE is universal or neutral so that it can be recognized and managed with any type of inkjet printer. You are therefore not bound to a particular type of printer.

The employee who prepares the "string" with everything that needs to be printed on the outer sheath of the cable can use the simple DRAG & DROP functions.

The operator in production loads the entire "marking string" into the inkjet marker, through a single simple click of the gun that reads the QR CODE: no possibility of error and a time of 2 seconds.

The composition of the marking is carried out by an office employee who can thus standardize the composition in the same way. You can save the "string" on the PC in the office by naming the file in the way defined at the company level (article code, order number, customer, type of cable, number and section of conductors ...). These files can therefore be traceable at any time. They can be copied and edited to create new ones. The files will also be saved in the central server which provides periodic backups, in a secure way.

The marking archive is managed in the office; for each cable to be produced, the QR code of the marking to be reported on the external sheath is attached to the production documentation (Order Confirmation, project / technical data for setting up the machines, required quality parameters, etc.).