The tests consist in submitting the sample to low or high temperature mechanical stress, such as bending, stretching and impact.

In fact, the samples must be submitted to a cooling or oven treatment before being tested in compliance with provisions for the various methods.

Through its collaboration with the most important testing and research institutes as well as comparing notes with customers and scrupulously analyzing regulatory requirements, SIF has been able to develop a product with particular attention focused on:

The tests involve uniformly rotating the spindle at a speed of one turn every 5 seconds, guiding the sample so that it folds into a tight helix, completely adhering to the spindle.

The diameter of the spindle and number of turns depend on the wire or cable thickness and type.

The cooling and test temperature, on the other hand, is defined by the standards for the specific type of mixture.

For the test to be validated, the sample’s insulating or sheathing material must not have any cracks upon visual examination without enlargement.

Equipment Features:

1. Testing equipment (manufactured based on the latest versions of the standards)

Operating temperature: up to -25° (-50° optional)

2. Interchangeable spindle kit - According to the type of cable to be tested

3. Series of interchangeable cable guide bushings - According to the type of cable to be tested

4. Manually operated version

5. Option for the automatic version

Punched samples, previously prepared according to the reference standard instructions, must be used for this type of test.

The equipment and sample’s cooling conditions vary according to the procedures followed.

The punched samples are attached to clamps as per the procedure described in the standards.

The test consists in applying traction to the sample based on the constant separation speed of 25 ± 5 mm/min.

The elongation must be determined by measuring the reference length increase at the time of breakage, if possible, or the distance between the clamps.

The test temperature, on the other hand, is defined by the standards for the specific type of mixture.

For the test to be validated, none of at least three valid tests must be at less than 20%.

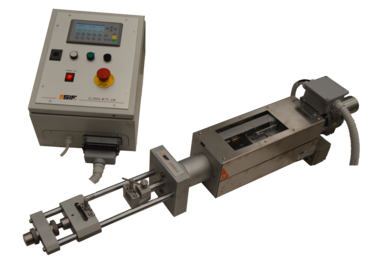

Equipment Features:

1. Testing equipment (manufactured based on the latest versions of the standards)

2. Traction group with standard geared motor - Operating temperature of up to -25°

3. Traction group with special geared motor - Version for operating temperature of up to -50°

4. Control panel to be positioned outside the refrigeration chamber - With PLC to manage tests, the display, the forward, backward, stop and emergency buttons as well as the on/off switch

5. Version with manual elongation detection

SIF INNOVATIVE SOLUTIONS

6. SIF ADEL@ AUTOMATIC ELONGATION DETECTION SYSTEM

Elongation measurement is performed automatically after the test and the value appears on the control panel display.

Three samples must be used for this type of test, taken from finished cable with a length as specified in the reference standards.

The equipment and sample’s cooling conditions vary according to the procedures followed.

The equipment must be kept inside the refrigeration chamber prior to and during the test.

After the cooling period, the test consists in positioning the samples one by one, as indicated in the standard, and then dropping a percussion instrument over the sample from a height of 100 mm.

The mass of the percussion weight depends on the type and size of the cable to be tested.

The sample is then subjected to torsion stress or immersion in hot water according to the standard.

For the test to be validated, the samples must not have any cracks upon visual examination without enlargement.

Equipment Features:

1. Testing equipment (manufactured based on the latest versions of the standards) - Operating temperature: up to -25° (-50° optional)

2. Kit of interchangeable percussion weights - According to the type of cable to be tested

Three samples must be used for this type of test, taken from finished cable with a length as specified in the standards.

The test consists in positioning the samples as indicated in the standard and allowing the blade, which is 0.70± 0.01 mm thick, to place perpendicular pressure on the sample axis.

The pressure to be applied is given by the formula shown in the standard.

The test is performed at a constant temperature at the value specified by the standard for the cable type, for example, inside a hot air oven.

The sample must be kept in the test position for a specific length of time, as established by the standard for the cable or by reference standard for the test.

At the end of the test period, the sample must be cooled.

When it has reached the right temperature, it must be removed from the equipment and prepared for evaluation according to the provisions.

For the test to be validated, the average incision value, measured on the three samples, must not exceed 50% of the average insulation thickness value.

Equipment Features:

1. Testing equipment (manufactured based on the latest versions of the standards)

2. No. 3 testing stations with blade

3. Interchangeable test cable support kit - Supplied with flat cable at 90°or 120°

4. Cable pressure weights kit