The STM series is available in:

AC, alternating current with a completely sinusoidal waveform, in the following models:

DC, direct current, in the following models:

The bead chains electrodes are available with length of 50 – 100 – 150 – 200 mm

(upper length or brushes instead of bead chains available on request)

| Bead chain electrode length | ||||||||

|---|---|---|---|---|---|---|---|---|

| TYPE | 50 mm m/min | 100 mm m/min | 150 mm m/min | 200 mm m/min | ||||

| CEI EN IEC | UL | CEI EN IEC | UL | CEI EN IEC | UL | CEI EN IEC | UL | |

| STM50 | 60 | 16 | 120 | 33 | 180 | 50 | 240 | 66 |

| STM250 | 300 | 83 | 600 | 166 | 900 | 250 | 1200 | 333 |

| STM07 | 840 | 231 | 1680 | 462 | 2520 | 700 | 3360 | 933 |

| STMDC | 3000 | 3000 | 3000 | 3000 | ||||

| All models comply with the Standards CEI – EN – IEC 62230, UL 1581, UL 444, BS5099, GOST 2290-78 | ||||||||

| MALL WIRE up to 30 mm diameter | BIG WIRE up to 250 mm diameter | |||||||

|---|---|---|---|---|---|---|---|---|

| TIPO | Monoblocco | Small | Vertical | Mini compact | Jacket | Big | Compact | Sliding compact |

| kV | kV | kV | kV | kV | kV | kV | kV | |

| STM50 | 15 | 15-25-30 | 15-25 | |||||

| STM250 | 15 | 15-25-30 | 15-25 | |||||

| STM07 | 15 | |||||||

| STMDC | 10-15-20-25 | 15-25-30 | ||||||

| See the SPARK TESTER types in the photos. Ask SIF for further informations. | ||||||||

ATTN. In this table you find an indication of the standard models, for any other request we invite you to contact our staff to offer you an equipment tailored to your needs!

Spark Tester with the characteristic of incorporating control unit and "electrode" (container, voltage generator, protection carter, bead chain electrode) into a single "monoblock" group.

This solution offers advantages such as: disturbances immunity, ease of installation, reduced size, attractive price.

This solution allows you anyway to move the display as it is to a small distance or to order the solution with the display mounted in a rack and move it away to control the Spark Tester remotely.

Spark Tester with traditional two-parts composition: control unit and separate electrode. In this case, the whole electronic part is mounted inside the control unit, therefore also the inputs and outputs, while the electrode can be mounted remotely.

Vertically mounted Spark Tester Monoblock, for example on machines for hanks or drums. It is equipped with a special bead chain tube that complies with the standards and therefore guarantees the prescribed speeds. There is no Spark Tester on the market, mounted in this position, which has a chain-type electrode complying with the Standards. With this model, SIF has solved this problem.

This solution allows you anyway to move the display as it is to a small distance or to order the solution with the display mounted in a rack and move it away to control the Spark Tester remotely.

Spark Tester with stainless steel protection carter to solve the problem of damage to the insulating plate due to moisture or water drops on the extrusion lines. This solution allows the electrode to last longer.

This solution allows you anyway to move the display as it is to a small distance or to order the solution with the display mounted in a rack and move it away to control the Spark Tester remotely.

Spark Tester with the characteristic of having a center distance of about 600 mm from the base to the passage of the cable. It is very useful for lines where the cable runs at lower heights or where you do not want to use the BIG model.

It includes the control unit and the "electrode" (container, voltage generator, protection carter, bead chain electrode) into a single group.

This solution allows you anyway to move the display as it is to a small distance or to order the solution with the display mounted in a rack and move it away to control the Spark Tester remotely.

Spark Tester with the characteristic of having an adjustable center distance between 980 and 1050 mm from the base to the passage of the cable.

It includes the control unit and the "electrode" (container, voltage generator, protection carter, bead chain electrode) into a single group.

This solution allows you anyway to move the display as it is to a small distance or to order the solution with the display mounted in a rack and move it away to control the Spark Tester remotely.

Spark Tester composed by three separate parts: Control unit, electrode (metallic carter and bead chain electrode) and generator unit (container and voltage generator) to solve the problem of damaging the insulating plate and the transformer due to humidity, or drops of water, on the extrusion lines. This solution allows the electrode to last longer.

This solution allows you anyway to move the display as it is to a small distance or to order the solution with the display mounted in a rack and move it away to control the Spark Tester remotely.

Spark Tester compact made in sliding version. Allows you to slide the electrode back and forth in order to move it from the line when not needed and then reposition it.

This version is equipped with: openable bead chain electrode, stainless steel brushes mounted in the lower part of the chain electrode to probe the large diameter cables (up to 150 mm), display mounted next to the electrode carter to simplify the operations of adjustment and visualization.

This solution allows you anyway to move the display as it is to a small distance or to order the solution with the display mounted in a rack and move it away to control the Spark Tester remotely.

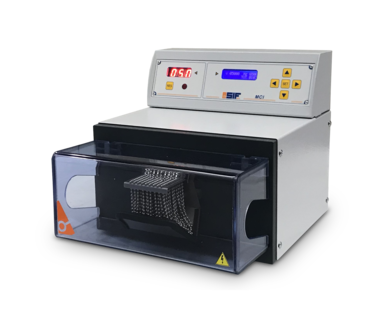

Integrated control panel MCI

User friendly, to set up of the following functions by the push-buttons ►▲▼◄ and SET:

3. SIF chooses to provide instruments with frequencies up to 700Hz because systems with frequencies above 2kHz have problems due to cable capacity. Most Spark Tester manufacturers DO NOT SHOW THE FREQUENCY MEASUREMENT and in the case of capacity automatically reduce the frequency without informing the customer/operator. SIF measures and shows the frequency on the display and allows the customer to adjust it manually, so to be always sure to be compliant with the standards.